In the fast-evolving flexible packaging industry, valued at USD 274.6 billion in 2024, a flawless package seal ensures product freshness, safety, and consumer satisfaction. Weak seals result in up to 10% production waste, costing manufacturers USD 5,000 per incident in rework, scrap, and downtime. Automatic packaging machines offer precision and consistency to eliminate these risks, delivering robust seals for diverse products. As a leading packaging machinery manufacturer, HIJPACK Machine provides automatic packing machines that achieve 99.9% seal reliability. This article explores four essential strategies for creating perfect seals, highlighting advanced solutions for food, pharmaceuticals, and household goods packaging.

A perfect seal safeguards products against moisture, oxygen, and contaminants, extending shelf life by up to 30% for items like snacks or coffee. Inadequate seals increase scrap rates by 10% and risk consumer trust due to leaks or spoilage. Automatic packaging machines, such as premade pouch and capsule filling systems, deliver ±0.1mm sealing precision, ensuring compliance with HACCP and GMP standards while cutting rework costs by 15%.

Achieving consistent seals requires precise equipment, materials, and maintenance. Automatic packing machines address common sealing challenges through innovative technology. Here are four critical strategies:

Uniform seal strength depends on consistent heat and pressure. High-quality automatic packaging machines use single-piece SS304 sealing jaws, coated with food-safe Teflon, maintaining 150–200°C heat and 0.5–1 MPa pressure. Unlike multi-piece jaws, which vary by 5–10°C, single-piece designs ensure 99.9% seal integrity, ideal for coffee capsule packaging. This reduces seal failures by 20%, enhancing reliability for high-speed operations.

Misaligned jaws create uneven seals, increasing leak risks by 15%. Advanced automatic packing machines feature servo-driven alignment systems, adjusting jaws with ±0.05mm precision. PLC controls trigger alignment checks during:

Machine startup

Material jams

Format changeovers

Maintenance cycles

This automation eliminates unsafe shimming, reducing downtime by 20% for applications like tea bag sealing.

Product residue, such as powders or liquids, in seal areas reduces adhesion by 25%. Automatic packaging machines incorporate:

Dust extraction hoods, removing 85% of airborne particulates.

Anti-static bars, cutting powder adhesion to films by 90%.

Nitrogen flushing, displacing dust for cleaner seams.

These features ensure pristine seals, lowering scrap by 10% for coffee pouch packaging.

Seal bar buildup or temperature deviations cause 30% of sealing failures. Automatic packing machines include maintenance schedules via touchscreen PLCs, with tasks like:

Daily cleaning of seal bars with SS304-safe solvents.

Weekly sensor checks for ±2°C temperature accuracy.

Monthly pressure calibration for 99.9% consistency.

On-site audits reduce unplanned downtime by 25%, ensuring reliable seals for pharmaceutical sachets.

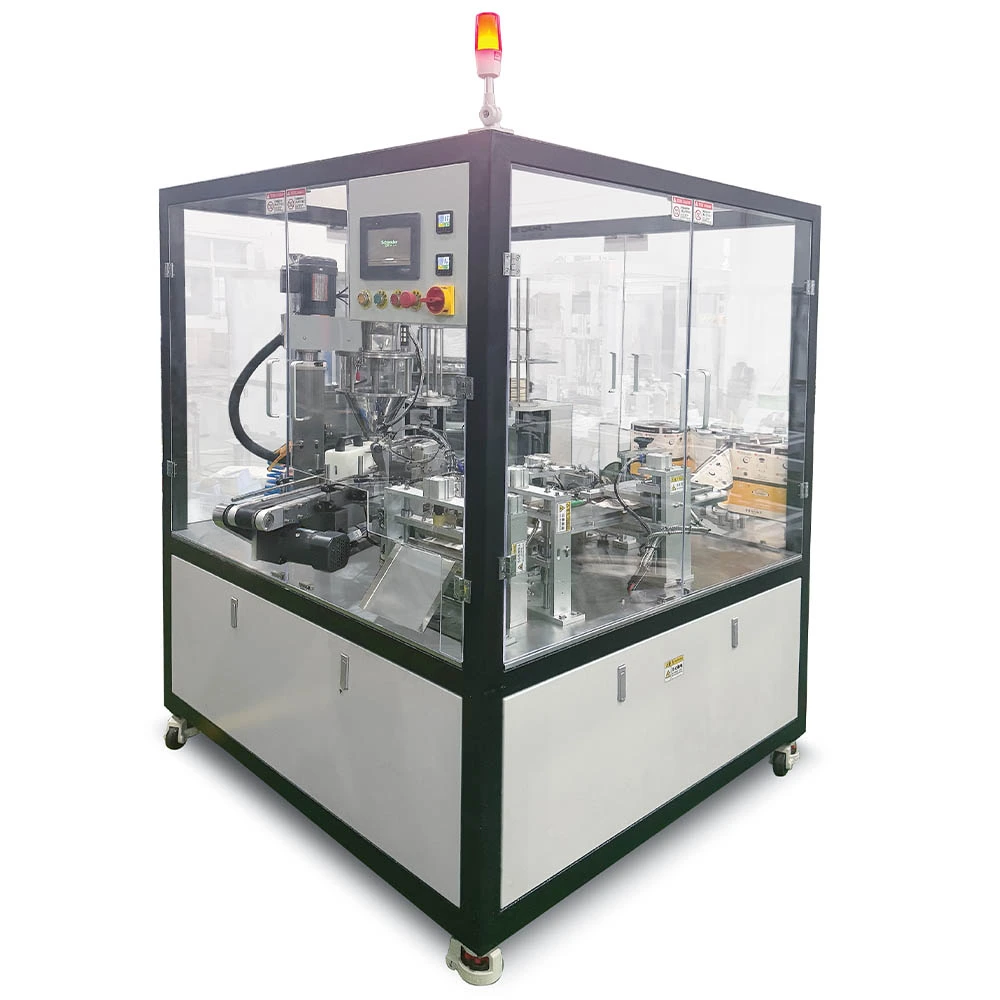

HIJPACK Machine’s automatic packaging machines are engineered for excellence:

The premade pouch packing system uses servo-controlled seal bars, achieving ±0.1mm accuracy at 60 pouches per minute. Ultrasonic sealing options minimize heat exposure by 50% for sensitive products, ensuring robust seals for snack pouches.

These machines handle 50–100μm films, including metallized polypropylene and biodegradable PLA, with adjustable sealing parameters. Nitrogen flushing reduces oxygen by 99%, enhancing seal durability for perishable goods like cheese.

Sensors track sealing temperature, pressure, and alignment, with PLC alerts for deviations. IoT integration enables remote diagnostics, resolving 70% of issues off-site, ensuring 98% defect detection.

Automatic packing machines deliver perfect seals for:

Food and Beverage: Coffee, tea, and snacks in 5–500g pouches, with 12-month shelf life.

Pharmaceuticals: Powders and tablets in sachets, meeting ISO 13485 standards.

Household Products: Detergent pods in water-soluble films, with leak-proof seals.

Pet Food: Kibble in 1kg bags, featuring resealable zippers.

Waste Reduction: 10% lower scrap, saving USD 2,000 annually.

Extended Shelf Life: 30% longer freshness, boosting consumer trust.

Efficiency: 20% less downtime, with ROI in 12–18 months.

Compliance: Adheres to HACCP, GMP, and EU recyclability standards.

As a global packaging machinery manufacturer, HIJPACK Machine offers:

Robust Engineering: Automatic packaging machines with SS304 frames and IP65 enclosures, achieving 99.9% uptime.

Sustainability: Support for compostable films, reducing waste by 10%.

Global Reach: 24/7 support at helen.machine@gmail.com, with spare parts delivery in 48 hours across 20+ countries.

Customization: Sealing solutions for 5g–5kg fills, from coffee capsules to pet food.