The global demand for powdered products, from ground coffee to pharmaceutical supplements, is driving innovation in packaging solutions. In 2024, the powder packaging market reached USD 2.4 billion, with single-serve formats like sachets and pouches growing at a 5.8% CAGR. Powder sachet filling and sealing machines and coffee capsule powder filling machines are critical for delivering consistent, hygienic, and shelf-stable products. As a leading packaging machine manufacturer, HIJPACK Machine offers advanced food powder packaging machines tailored to diverse industries. This article explains how these machines operate, their key components, and why HIJPACK Machine is your ideal partner for powder packaging.

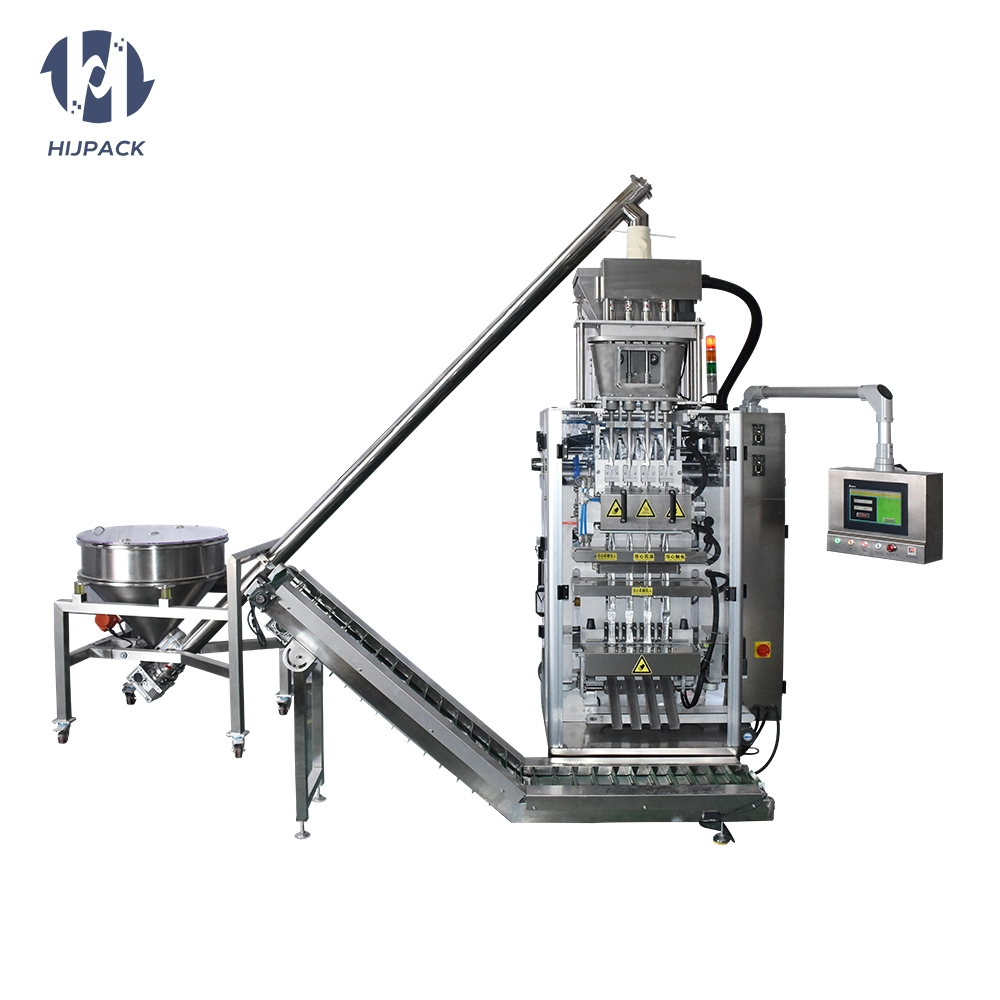

Powder sachet filling and sealing machines automate the process of dispensing dry powders into containers like sachets, pouches, or capsules, then sealing them to ensure freshness and safety. These machines handle free-flowing powders (e.g., spices, sugar) and non-free-flowing powders (e.g., milk powder, protein supplements) with precision. HIJPACK Machine’s systems, such as the Vertical Form Fill Seal (VFFS) Machine and K-Cup Filling Machine, achieve filling accuracies of ±0.5g and sealing rates up to 60 pouches per minute, ideal for coffee capsule powder filling and pharmaceutical applications.

The process involves forming or loading containers, filling them with measured powder, and sealing them hermetically. Machines vary by automation level (semi-automatic or fully automatic) and container type (premade pouches, roll-film sachets, or capsules). HIJPACK Machine supports diverse formats, from 5g stick packs to 100g pouches, ensuring versatility for global markets.

The operation of powder pouch filling machines follows a streamlined sequence, with each step optimized for accuracy and efficiency. HIJPACK Machine’s systems feature 6–8 stations, typically arranged in a rotary or vertical layout, depending on the model.

The process begins with loading premade pouches or feeding roll-stock film. In HIJPACK Machine’s VFFS Machines, a continuous film (e.g., metallized polypropylene) is shaped into pouches using a forming collar, achieving bag widths from 50–200mm. For premade pouches, our K-Cup Filling Machine uses a magazine to feed containers, with vacuum suction ensuring precise placement. This step supports powder sachet packaging for spices or coffee, minimizing manual labor.

To prepare for filling, pouches are opened using suction pads and air blowers. HIJPACK Machine’s systems integrate sensors to detect improper opening, ensuring no powder is dispensed into faulty pouches. For coffee capsule powder filling machines, capsules are aligned under filling heads, with nitrogen flushing to preserve aroma, extending shelf life by 30%.

The core step involves dispensing powder using an auger filler, ideal for both free-flowing and non-free-flowing products. HIJPACK Machine’s auger systems rotate at adjustable speeds, achieving ±0.5g accuracy for weights from 2–50g. For example, our powder sachet filling machine handles coffee powder with a 10L hopper, while our food powder packaging machine supports larger 50L hoppers for high-volume production. Dust hoods minimize airborne particulates, ensuring hygiene for pharmaceutical powders.

Powder filling generates dust, which can affect sealing quality. HIJPACK Machine’s powder pouch filling machines include dust collectors to remove particulates from seam areas. Optional settlers gently vibrate pouches to compact powder, optimizing space and reducing air pockets, critical for powder sachet packaging of protein powders.

Hermetic sealing ensures product integrity. HIJPACK Machine’s powder sachet filling and sealing machines use heated seal bars (150–200°C) to bond pouch layers, creating airtight seams. For coffee capsule powder filling, our machines apply foil lids with ±0.1mm precision, supporting aluminum or compostable materials. Nitrogen flushing before sealing enhances freshness for up to 12 months.

A cooling bar strengthens seals by lowering seam temperatures, ensuring durability during transport. Finished pouches or capsules are discharged onto conveyors for labeling or boxing. HIJPACK Machine’s systems achieve 99.9% sealing success rates, with output rates of 3,000–4,800 units per hour for powder sachet filling machines.

HIJPACK Machine’s food powder packaging machines rely on advanced components to ensure precision and durability:

Hopper: Stores bulk powder, with capacities from 10L to 120L. Stainless steel (SS304) construction prevents corrosion, ideal for powder sachet packaging of spices or detergents.

Auger Filler: A screw mechanism dispenses powder with ±0.5g accuracy, adjustable for 0.5–100g fills. Agitator blades prevent clumping in non-free-flowing powders like milk.

PLC Control System: A 10-inch touchscreen enables real-time adjustments, supporting multilingual interfaces for global clients.

Sealing Mechanism: Heated bars or ultrasonic systems ensure robust seals, compatible with PLA-based biodegradable films for sustainable powder pouch filling.

Sensors: Detect pouch alignment and filling errors, reducing waste by 2–5% compared to manual processes.

HIJPACK Machine’s powder sachet filling and sealing machines serve diverse sectors:

Food and Beverage: Coffee capsule powder filling machines package instant coffee and tea powders, while food powder packaging machines handle spices and flour in 5–50g sachets.

Pharmaceuticals: Precise dosing for paracetamol or protein powders in stick packs, with GMP-compliant hygiene.

Cosmetics: Compact sachets for face powders, using dust-proof systems to maintain purity.

Chemicals: Detergent powders in 10–100g pouches, with robust seals to prevent leakage.

HIJPACK Machine’s powder pouch filling machines offer unmatched advantages:

Auger fillers and PLC controls ensure ±0.5g accuracy, reducing product giveaway by 3% compared to manual filling, ideal for coffee capsule powder filling.

Automated systems produce 60 pouches per minute, boosting output by 50% over semi-automatic alternatives. HIJPACK Machine’s VFFS Machines minimize downtime with tool-free changeovers.

Support for biodegradable films aligns with Europe’s 2030 recyclability goals, reducing material waste by 10% for powder sachet packaging.

From 5g stick packs to 100g pouches, our machines adapt to regional preferences, such as Japan’s premium coffee capsules or India’s spice sachets.

As a trusted packaging machine manufacturer, HIJPACK Machine delivers food powder packaging machines with global reach:

Advanced Manufacturing: Our Jiangsu facility produces powder sachet filling machines with SS304 frames, achieving 99.9% uptime. We support 2–50g fills with ±0.1g accuracy for high-value powders.

Quality Assurance: Certified to ISO 9001 and CE, our machines undergo 100% testing, ensuring compliance with HACCP standards for coffee capsule powder filling.

Global Support: Serving 20+ countries, we offer on-site installation and 24/7 technical support at helen.machine@gmail.com.

Competitive Pricing: Strategic supplier partnerships reduce costs by 15%, making powder pouch filling machines accessible for startups and large brands.

To maximize powder sachet filling and sealing machine performance, follow these HIJPACK Machine guidelines:

Select Film Type: Use metallized films for powder sachet packaging to extend shelf life by 30%.

Calibrate Augers: Adjust rotation speeds for free-flowing powders like sugar to maintain ±0.5g accuracy.

Implement Dust Control: Install hoods to reduce airborne particulates by 80% during food powder packaging.

Regular Maintenance: Clean hoppers biweekly to prevent clumping, ensuring 99.9% uptime.

Powder sachet filling and sealing machines are transforming the packaging of coffee, spices, and pharmaceuticals, offering precision, efficiency, and sustainability. HIJPACK Machine leads the industry with food powder packaging machines that deliver ±0.5g accuracy and 60 pouches per minute. From coffee capsule powder filling to powder pouch filling, our solutions meet global demands across diverse markets. Visit https://www.hijcoffeepack.com/ to explore our powder sachet filling machines and elevate your packaging operations with HIJPACK Machine.